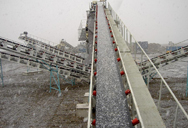

Site safety and safer aggregate crushing

2020.4.17 There are many key priorities to consider when ensuring overall site safety and safer crushing operations. Safety requires proactive intervention to prevent workplace accidents. Each company or site should have clear safety

consulter en ligne

Safety Tips for Crushing Screening Aggregate Equipment

Crushing and screening machinery present substantial risks in the aggregate industry. These sizable pieces of equipment can be difficult if not operated with the highest level of respect and

consulter en ligne

Grain Handling Safety Guide - AgHealth Australia

2019.5.20 The document briefly gives guidance on the hazards and risks associated with grain production and handling in the farm setting, and practical guidelines on how to

consulter en ligne

Grain Handling - Overview OSHA.gov Occupational Safety

2024.11.1 These hazards include: fires and explosions from grain dust accumulation, suffocation from engulfment and entrapment in grain bins, falls from heights and crushing

consulter en ligne

Safe operation and use of mobile jaw crushers - HSE

2024.10.29 Key risks. Machinery guarding. Clearing Blocked or Stalled Crushers. Slips and trips. Transport – coming in to contact with excavators loading the crusher. Mobile crushers

consulter en ligne

8 Tips for Crusher Safety Stewart-Amos

2022.10.27 Operate every crusher at an appropriate capacity to ensure rock crushing plant safety. Keep platforms and areas around the machine clean, and monitor the crusher’s lubrication, flow, temperature, wear and pressure at

consulter en ligne

Site Safety and Safer Aggregate Crushing

2019.9.11 McLanahan discuss the key priorities for ensuring overall site safety and safer crushing operations. Safety requires proactive intervention to prevent workplace accidents. Each company or site should have clear safety

consulter en ligne

6 ways to improve crushing safety - Metso

2020.5.4 Machines that aren’t maintained well are far more likely to malfunction and cause harm to people on crushing sites. It’s important to take a preventative maintenance approach; instead of waiting for things to break,

consulter en ligne

10 Ways to Improve Crushing Safety Today

2023.5.18 To ensure the safety of personnel and assets, it's crucial to implement effective safety measures. This article explores ten ways to improve crushing safety, helping organizations maintain a safe and efficient work

consulter en ligne

A STUDY OF RISK AND SAFETY MANAGEMENT

2015.1.1 Study of this paper involves finding of 46 factors which are responsible for risk and safety in aggregate crushing plant. Findings are based on literature review, structured interview with plant ...

consulter en ligne

Safety First: Best Practices for Operating Plastic

2023.12.16 Plastic crushers play a vital role in waste management and recycling processes, offering an efficient solution for reducing plastic waste to manageable sizes.While these machines contribute significantly to

consulter en ligne

Grinding machines safe operation and

2023.7.6 Safe Operation of Grinding Machines 1- Read the Manual. Before using a grinding machine, it is important to read the manual carefully. The manual will provide information on the proper use of the machine, including safety

consulter en ligne

The Importance of Regular Maintenance for Hammer

2023.2.23 Safety Precautions for Hammer Crusher Operation. Hammer crushers are powerful machines that can crush large rocks and other materials with ease. However, they can also pose a serious risk to operators if proper safety precautions are not taken. Here are some of the key safety precautions that should be followed when operating a hammer crusher:

consulter en ligne

Confined Space Safety: A Crucial Guide for Workers

2024.11.6 Confined space safety, mastered! Learn about hazards, regulations, and best practices. ... This guide helps you learn about the safety precautions and practices that can keep the lives of employees and workers safe. ... Loose materials like grains, sand, and liquid can lead to crushing and suffocation. Moving machinery can cause entanglement ...

consulter en ligne

10 Machine Safety Rules You Should Follow - Rowse

2020.8.24 Anyone working with, or around machinery needs to be alert to potential dangers at all times. As machines continue to become more high-tech and complicated, we must also keep up to date on new advances in Industry 4.0, and how best to protect ourselves.For this reason, you should make sure that all your staff and employees are familiar with machine

consulter en ligne

Types of Crushers: Choosing the Right One for Each Stage

2024.7.17 Fine crushing: Utilize sand making machines, roll crushers, fine crushers or compound crushers in tertiary crushing to produce fine sand or powder. 4. Capacity requirements Determine the hourly capacity needed. Choose gyratory or cone crushers for large-scale production lines, and jaw or impact crushers for medium to small-scale operations.

consulter en ligne

Working safely with machines - Hesperian Health Guides

2024.7.6 Putting individual lock out and block out instructions with pictures on each machine helps workers be sure they are doing it the right way for each machine. Reinstall guards and other safety devices. Machine technicians and maintenance workers sometimes remove guards and disconnect safety devices while they work on a machine.

consulter en ligne

the malt grain crushing machines for breweries - CBS

2024.10.31 Professional, very robust four-rollers malt grain squeezing machine with production capacity 1200 kg of malt per hour, the motor power is 5.5 kW. A powerful electrical mill for preparation of malt grist from malted grains. Wide cylinders with fine adjusting ensure to the safe squeezing of grains without damage external parts of grains.

consulter en ligne

MACHINE SAFETY - IIT Bombay

2020.12.4 Safety precautions while working with machinery •Stop the machine before measuring, cleaning or making any adjustments. •Do not handle metal turnings by hand as they can cause injury. Use brush or rake to remove turnings. •Keep hands away from the cutting head and all moving parts. •Cutting tools and blades must be clean and sharp, so that ...

consulter en ligne

Important Milling Machine Safety Precautions

2023.12.6 Milling machine safety precautions are crucial for preventing accidents and ensuring a safe working environment. Operators must always wear appropriate personal protective equipment, including safety glasses, hearing

consulter en ligne

Machine Moving Parts Safety - Global EHS

2024.11.9 Machine moving parts Safety is an important part of workplace safety, especially in industries that use heavy machinery. If proper safety precautions are not in place, machine moving parts like gears, belts, and

consulter en ligne

Safety First: Precautions for Operating Limestone Crushing

2024.4.7 In this article, we'll highlight the essential precautions that operators should follow when operating limestone crushing equipment to ensure the safety of personnel and prevent accidents ...

consulter en ligne

Safety Tips for Crushing Screening Aggregate Equipment

Crushing and screening machinery present substantial risks in the aggregate industry. These sizable pieces of equipment can be difficult if not operated with the highest level of respect and care. Focus on safety is crucial, not only to comply with regulations but to protect the lives and well-being of staff.

consulter en ligne

safety precaution pulverizer mill Mining Quarry Plant

2013.3.25 pulverizer machine. Mill (Crusher): Turbo Mill, Pin Mill, Vertical Mill, pulverizing safety precautions; coal pulverizing equipment; laxmi pulverizing mills p ltd;

consulter en ligne

Top 10 Safety Precautions for Operating a Press Metal Machine

2024.6.13 To prevent accidents and injuries, it is crucial to adhere to proper safety protocols. This article presents the top 10 safety precautions for operating a press metal machine to ensure a safe work environment. 1. Adequate Training and Authorization. Only authorized and adequately trained personnel should operate press metal machines.

consulter en ligne

Top 10 Safety Precautions to Take Around Grain and Silage

When it comes to the harvesting, transportation and storage of grain and silage, the process can be hazardous. Potential grain and silage risks include machinery entanglement, falls from building and machinery, electrocution, and even suffocation. Here are 10 tips to keep you and your family safe around grain and silage: 1.

consulter en ligne

Safety Precautions while Working on Lathe Machine

2015.12.23 1. One should always be sure that all guards are in place before running the machine. 2. Always clamp the work and tool properly with correct size of work and tool holding device.

consulter en ligne

Lifting Safety : Crane Rigging Safety Guidelines - Hazards Precautions

Instability:. Unsecured Load: An improperly secured load may shift unexpectedly, causing the crane to become unbalanced and possibly tip over.; Load Capacity Exceeded: Operating a crane beyond its rated capacity is a common cause of accidents.It is crucial to adhere to the specified load capacities to maintain stability. Ground Not Level or Too Soft: Operating on unstable

consulter en ligne

A Complete Guide to Machine Safety - RS Components

2023.1.12 The addition of machinery safety systems that use switches, sensors, and opto-electronicprotective devices to monitor how the operator is interacting with a machine is a secondary way to mitigate risks when physical guarding is impractical.

consulter en ligne

>> Next:Machine De Calcaire De L'Inde

- portable les types de pierre

- meulage des rails philosophie

- de cout de concasseurs de pierre en inde

- combien cote un moulin minerai de balle

- fournisseurs de l usine modèle de broyage cyclotec en inde

- principe de moulins à rouleaux

- fabricants de fer Indonésie friser en algérie

- Rfrences des plantes d'enrichissement du minerai de fer

- pierre concasseur Indonésie vendre guwahati

- Film de ponceuse abrasive

- concasseur à cone irlande

- Ligne de production de broyage de phosphate au Sri Lanka

- fabricants de machine de broyage de câbles en cuivre

- bonbons ecrasement niveau de la saga 181

- machines pour la fabrication de quartz