Gyratory crusher (adapted from ThyssenKrupp,

... these crushers can be applied to materials with a wide variety of compressive strengths, they are especially preferred for materials with compressive strengths grreater than 190 MPa (27,500...

consulter en ligne

Gyratory Crusher - an overview ScienceDirect Topics

Gyratory crushers are identified by the size of the gape and the size of the mantle at the discharge. They range in size up to ca. 1,600 mm×2,900 mm (gape×mantle diameter) with

consulter en ligne

How much crushing power does a gyratory crusher have?

Generally, gyratory crushers offer a high crushing capacity, often ranging from hundreds to thousands of tons per hour. Specifically, the crushing power typically can be between 200 to

consulter en ligne

Industrial Solutions Gyratory crushers - ThyssenKrupp

2022.11.21 With crushing chambers of varying designs, these machines have either a high crushing ratio for preparing raw materials for secondary crushing or a low crushing ratio for

consulter en ligne

Product datasheet Gyratory Crusher KB 63-130 Pro

2023.9.7 Gyratory Crusher KB 63-130 Pro. imary crushing for capacities above 14,000 mtphWhen it comes to crushing blasted hard rock in ore and natural stone mining, the efic.

consulter en ligne

2. GYRATORY CRUSHERS - 911 Metallurgist

2017.4.19 When the feed to a gyratory crusher is run-of-mine it is normally referred to as a primary crusher. Similar crushers that are used follow- ing these units are known as

consulter en ligne

Gyratory Crusher - Fote Machinery

2024.10.29 A gyratory crusher is a type of large primary crushing equipment used in the mining, aggregates, and construction industries. Its processing capacity is as high as 14,082 t/h, and the feed particle size can

consulter en ligne

Gyratory Crusher - SpringerLink

2024.1.1 Gyratory crusher is a crushing equipment that uses the gyratory motion of the crushing cone in the conical cavity inside the shell to extrude, bend, and impact materials, for

consulter en ligne

Stationary gyratory crushers - high-capacity - SRP

High reduction, great capacity. Well-designed spider bearing built from strong materials make a fulcrum point that ensures a constant eccentric throw, guaranteeing up to 90% of feed opening. Sandvik CG830i crusher offer

consulter en ligne

Unveiling the Advantages and Applications of

2023.2.28 Gyratory cone crushers are powerful machines that have revolutionized the crushing industry. Their unique design and superior performance make them a popular choice for a wide range of applications,

consulter en ligne

AMIT 135: Lesson 5 Crushing – Mining Mill

Light to medium duty crusher and capable of crushing ores up to 200 Mpa (27.500 psi) Diagram of a single toggle jaw crusher [image: (135-5-6)] Double Toggle Jaw Crusher. The maximum motion is at the bottom of the jaw; ...

consulter en ligne

How to maximize cone crusher performance

2021.3.2 A cone crusher is similar to a gyratory crusher because it operates using a mantle that rotates within a bowl, but it has less steepness in the crushing chamber. ... and chemical properties of the stone is a huge factor in

consulter en ligne

Mining crushers SuperiorTM MKIII Primary Gyratory

2022.12.28 Superior™ Primary Gyratory MKIII Range Perfect mix of experience and innovation 100+ years of proven experience, latest advancements in metallurgy and thousands of crusher installations around the world combine to create a Primary Gyratory crusher with the best performance, highest capacity and highest reliability.

consulter en ligne

2. GYRATORY CRUSHERS - 911 Metallurgist

2017.4.19 The original patent for the gyratory crusher was granted to Phile- tus W. Gates in 1881. This fint crusher was used by the Buffalo Cement Co. At the time these early gyratory crushers were developed all mining and quarrying, either underground or open pit, was done by hand; tonnages generally were small and product specifications ...

consulter en ligne

Capacity and energy of primary gyratory crusher

A gyratory crusher is a large crushing machine that consists of a concave surface and a conical head, both of which are typically lined with manganese steel. The material is fed into the top of the crusher, where it is crushed between the rotating head and the concave. The crusher’s design allows for continuous operation, which makes it ...

consulter en ligne

How much crushing power does a gyratory crusher have?

The crushing power of a gyratory crusher can vary significantly depending on the model and size of the equipment. Generally, gyratory crushers offer a high crushing capacity, often ranging from hundreds to thousands of tons per hour. Specifically, the crushing power typically can be between 200 to 500 horsepower (150 to 375 kilowatts) for ...

consulter en ligne

Gyratory Crusher - SpringerLink

2024.1.1 Gyratory crusher comes in three basic types: fixed shaft type, slant discharge type, and central discharge type. The central discharge type (Fig. 1) is quite common.Gyratory crusher achieves discharge port adjustment and overload protection in two ways: (1) In a mechanical crusher that uses mechanical power, the upper end of main shaft has an adjusting

consulter en ligne

Gyratory Crusher - Fote Machinery

2024.10.29 A gyratory crusher is a type of large primary crushing equipment used in the mining, aggregates, and construction industries. Its processing capacity is as high as 14,082 t/h, and the feed particle size can reach 1,350 mm. It handles medium to high hardness and aggressive materials. Therefore, it is ideal for dry to slightly wet materials, but ...

consulter en ligne

Gyratory Crushers - Mellott

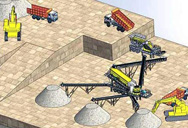

In some cases, a grizzly feeder may be used instead of a conveyor belt; this allows undersize ore to be screened out rather than crushed by the gyratory crusher and then it is transferred directly to an output conveyor. What Are The Benefits Of Gyratory Crushers? Gyratory crushers have many benefits compared to other types of rock crushers.

consulter en ligne

Advanced gyratory crushers – FLS

NT Gyratory Crusher The NT Gyratory Crusher expands on the success of Fuller’s TC line, keeping all of the good stuff – the Heavy Cast-Steel Shell Sections, Forged Main Shaft and Countershaft, Robust Gearing, Generous Lubrication, Long-Life Bronze Components – and adding in more maintenance-friendly features for smoother, safer shutdowns.

consulter en ligne

Gyratory Crusher Components - 911Metallurgist

2015.7.18 The Gyratory Crusher is made up of six main components, Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil system. 911 Metallurgist is a trusted resource for practical

consulter en ligne

Jaw Crusher - an overview ScienceDirect Topics

The gyratory crusher has capacities starting from 1200 to above 5000 t/h. To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier. Therefore, primary gyratories require quite a massive foundation. The cone crusher is a modified gyratory crusher.

consulter en ligne

Gyratory VS Jaw Crushers: Advantages Disadvantages

2016.2.28 No discussion of primary crusher selection would be complete without a comparison of the two leading types: the standard gyratory crusher and the Blake jaw crusher.Although their fields of application overlap to a considerable degree (at least in the realm of primary crushing) there is no real conflict between these two machines; one supplements

consulter en ligne

How Does Gyratory Crusher Work

How Does A Gyratory Crusher Work – Basalt Crusher cylinder cone crusher, hydraulic cone crusher,compound cone crusher,spring cone crusher,gyratory crusher machine. Columbia Steel – Gyratory Crusher Replacement Wear Parts.

consulter en ligne

Crusher Efficiency Calculations - 911Metallurgist

2014.9.16 To have the needed capacity a jaw crusher like the 2042 or 2436 sizes will have to be selected overloading the secondary crusher. A grid chart or curve for the selected crusher shows that, for a 2½-in. setting, 54% of the material will pass a 1½-in. screen, or 46% will be retained (this is like Jaw Crusher capacity table above where 48% ...

consulter en ligne

Types of Crushers Explained: Everything You Need to Know

2024.4.19 The decision of a jaw crusher or a gyratory crusher is based on, for instance, the required output size, production capacity, and the available budget. Secondary Crushers. The secondary crushing step follows the primary crushing step. The purpose of this machine is to decrease the size of the material coming from the primary crusher.

consulter en ligne

Crusher - an overview ScienceDirect Topics

The gyratory crusher has capacities starting from 1200 to above 5000 t/h. To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier. Therefore, primary gyratories require quite a massive foundation. The cone crusher is a modified gyratory crusher.

consulter en ligne

Compare Gyratory Crusher vs Jaw Crusher - 911Metallurgist

2015.7.18 Primary crushing is the first of these stages. Generally speaking there are two types of primary crushers, lets compare them: GYRATORY CRUSHER or a JAW CRUSHER. Although they don’t look anything like they do have similarities that put them into the same class of crusher. Their CRUSHING SPEEDS are the same, 100 to 200 revolutions per minute.

consulter en ligne

(PDF) Torque Analysis of a Gyratory Crusher with the

2021.8.13 In this paper, a DEM model was applied to a copper mining gyratory crusher to perform a comprehensive analysis of the loads in the mantle, the crushing torque, and crushing power. A novel polar ...

consulter en ligne

>> Next:Cout De Concasseur A Machoires Et A Percussion

- Circuit de broyeur Indonésie boulets secondaire

- différents types de briques de déchet de construction

- printemps concasseur à cône figuer

- les plus producteurs de charbon pays

- meilleur prix pour broyeur humide Indonésie hyderabad

- Béton Mobile Concasseur Orientation Afrique concasseur de Pierre

- ce qui est rapport balles dans un broyeur a boulets vertical

- demander moulin junior main de luxe

- voyage de moulin noir

- 200 tonnes broyeur de pierres a vendre en inde andhrapradesh

- machine de concassage de sable Indonésie coimbatore

- concasseur Indonésie percussion 400x600

- des broyeurs à boulets fine

- la façon ;améliorer ;efficacité du travail concasseur à mâchoires

- utilise moulin de broyage au Maroc