Manganese Mining and Processing: Everything

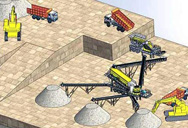

2014.5.7 More than 25 million tons of manganese are mined every year. Most manganese mining occurs in open pits. Although there are processes in place to mine manganese nodules in the ocean floor, they cannot complete

consulter en ligne

Everything to Know About the Manganese

2022.3.20 The mine is one of the world’s largest producers of manganese and has generated more than 115Mt of manganese ore and concentrate since June 2018 by utilizing this open-pit mining method. Manganese can also be

consulter en ligne

MANGANESE MINING AND TRANSPORT - International Manganese

6 天之前 Manganese ore: Manganese ore is usually transported by truck and train from the mine to the buyer (Manganese alloy smelter or trading warehouse), and if exported, it is loaded on

consulter en ligne

From Ore Body to High Temperature Processing of Complex Ores: Manganese ...

2020.8.21 The newer plant is at the Kalagadi manganese mine and was built to produce 2.4 million tons of manganese ore sinter annually and opened in December 2012. This

consulter en ligne

MANGANESE VALUE CHAIN - RAW MATERIAL OUTLOOK

2023.6.19 Approximately 90% of the global manganese trade is in the form of manganese ore (as-mined and sintered concentrate from bene ciation). Manganese is also traded in the

consulter en ligne

A global life cycle assessment of manganese mining

2019.10.20 Manganese can be mined using underground mining or surface mining methods depending on the ore deposit and the fineness of the ore (Zywicka, 2004). The

consulter en ligne

Comprehensive Study on Mineral Processing

2024.2.26 The target mineral of the Chongqing Chengkou manganese ore sample is carbonate manganese ore (rhombic manganese ore), the content of which is up to 82.9% in manganese minerals, and a small amount of silicate

consulter en ligne

Hydrometallurgical Processing of Manganese Ores: A

2014.5.28 In the hydrometallurgical processing of manganese from its ore, the leach liquors often contain divalent ions such as iron, manganese, copper, nickel, cobalt and zinc

consulter en ligne

Cradle-to-gate life cycle assessment of global manganese alloy ...

2016.2.8 The LCA was a cradle-to-gate study spanning the extraction of manganese ore and manganese smelting in submerged electric arc furnaces and associated on-site and off

consulter en ligne

Manganese Ore Processing - 911Metallurgist

2016.4.27 The Manganese Ore Processing Plant Crushing and Sampling of Manganese Rock. The flowsheet incorporates a conventional multistage crushing plant with a grizzly or screen ahead of both the primary and

consulter en ligne

From Ore Body to High Temperature Processing of Complex Ores: Manganese ...

2020.8.21 Manganese is considered a relatively rare metal as concentrations of it in ore of commercial importance are geographically limited. In nature, manganese is found in the form of oxides, carbonates, and silicates. Manganese ores are complex in the sense that they not only consist of a complex oxide mineral assemblage but these minerals are also very finely inter

consulter en ligne

MANGANESE VALUE CHAIN - RAW MATERIAL OUTLOOK

2023.6.19 Manganese ore mining is a mechanised large-scale activity. Although there are large terrestrial manganese resources, with the metal occurring in ... iron and/or silicon and modifying the process. Manganese ore is the primary source of manganese used in the manufacture of manganese ferroalloys. To be used in this way, as-mined manganese ...

consulter en ligne

Ecotoxicological consequences of manganese mining

2023.1.1 The primary and natural source of Mn is the crustal rock which is formed by the erosion process. Erosion of rocks and soils, mining activities, ... Isolation, identification and screening of manganese solubilizing Fungi from low-grade manganese ore deposits. Geomicrobiol J., 34 (2016), pp. 309-316, 10.1080/01490451.2016.1189016. Google Scholar

consulter en ligne

Manganese (Mn) Ore Minerals, Occurrence, Deposits

2023.4.23 Manganese is a chemical element with the symbol Mn and atomic number 25. It is a hard, brittle, silvery-gray metal that is commonly found in the Earth's crust. Manganese is an essential trace element that plays a crucial role in many biological processes, including metabolism, bone formation, and antioxidant function. It is also used in various industrial

consulter en ligne

Towards sustainable extraction of technology materials

2021.9.21 The potential benefit of such an approach has been illustrated in the case of iron ore mining, although limited to ore extraction and not including the processing stages, by using a carbon ...

consulter en ligne

5 Commonly Used Manganese Processing Methods - Mining

2021.6.29 Jig is for processing coarse and medium-grained manganese ore, and shaking table is for processing fine-grained manganese ore. Because the density of manganese oxide ore such as pyrolusite, pyrolusite, and brown manganese ore is about 4g/m³, which is significantly different from the density of silicate gangue, most of them can use gravity ...

consulter en ligne

Iron Ore Processing: From Extraction to Manufacturing - Mining

2024.4.26 The extracted ore undergoes further processing to separate the valuable iron-bearing minerals from the impurities and gangue minerals, as described in the subsequent stages of iron ore processing. Exploration and extraction are vital steps in the iron ore processing chain, as they determine the presence and viability of iron ore deposits.

consulter en ligne

Manganese Mining and Processing for Investors, Explained

3 天之前 The main purpose of processing Manganese ore is about producing a specific and acceptable grade of Manganese, where the objective is for maximum recovery of the Manganese. The beginning of the Manganese ore processing involves a multistage crushing workflow. From there, the production of ferromanganese, the manganese ore is mixed with iron ore ...

consulter en ligne

Top 10 Manganese Beneficiation Machines for Efficient Processing

2024.4.28 This allows for better interaction between the ore and the beneficiation chemicals, leading to higher recovery rates and better product quality. Ball mills are commonly used in the final stage of manganese ore processing before the ore is sent for further beneficiation. Ball mill - top 10 manganese beneficiation machines

consulter en ligne

What are the Methods of Manganese Processing? Mining

2023.11.27 The journey of manganese processing begins with ore mining and extraction. Manganese ores are typically found in abundance and occur in various forms, including pyrolusite, psilomelane, and rhodochrosite. Open-pit or underground mining techniques are employed to extract manganese ore, which is then transported to processing facilities.

consulter en ligne

7 Common Manganese Mining Processes

In the actual production, the manganese carbonate ore mining process mostly uses the strong magnetic separation process, the heavy medium dressing process and froth flotation process and so on. Manganese oxide ore mining process mainly adopts the gravity separation process, like ore washing-gravity separation process or ore washing-reduction ...

consulter en ligne

Manganese Mining and Extraction Manganese

2024.6.6 It is the second-largest producer, holding about 15% of the world's manganese reserves and producing 3 million tonnes of manganese per year. The mining process involves open-pit mining, and it is regarded as the

consulter en ligne

Five Common Types Of Manganese Ore Processing Solutions

2023.8.7 Manganese is a type of common metal mineral in nature. More than 150 types of manganese minerals have been discovered so far, but only a small portion of manganese ore with mining and utilization value, mainly including pyrolusite, psilomelane, bog manganese ore, etc. Manganese has become an essential strategic mineral resource among countries and apply in

consulter en ligne

Equipment Required To Build A Manganese Ore Processing

2024.11.11 This is usually achieved using jaw crushers or impact crushers, which can effectively reduce the size of the ore to facilitate subsequent processing. Once the ore is crushed to the appropriate size, it enters the grinding stage, where the manganese ore is refined into a fine powder using specialized equipment such as ball mills or vertical ...

consulter en ligne

Start of mining and processing marks new chapter for Menar

2022.2.3 East Manganese is an opencast mining operation with a 900 000 tons reserve. The manganese is extracted from three layers and blended to a grade of 36.5% manganese. We are in the process of ramping the mine up to produce 30 000 tons a month of run of mine manganese ore within the next three months.

consulter en ligne

Manganese Minerals Mining Manganese Ore Supplier Manganese Mining ...

Manganese Minerals is a privately owned Junior Mining Company that focuses on the development of manganese mining projects in South Africa with future plans to expand its operations to the Region. We mine Manganese ore, ensuring that medium grade manganese ore is made available to clients within specifications.

consulter en ligne

Transparency on greenhouse gas emissions from mining to

2020.2.3 For example, mining, processing and transportation require fuel and electricity, and the decomposition of carbonate minerals, employed to reduce environmental impacts, also releases carbon dioxide ...

consulter en ligne

Manganese Metallurgy - SpringerLink

2023.6.27 Manganese in natural manganese ores mostly exists in the form of oxides, carbonates, and silicates. Manganese minerals with industrial value mainly include pyrolusite (MnO 2), psilomelane (mMnOMnO 2 nH 2 O), manganite (Mn 2 O 3 H 2 O), braunite (Mn 2 O 3), and hausmannite (Mn 3 O 4), as well as rhodochrosite (MnCO 3) and rhodonite (MnOSiO

consulter en ligne

A Comprehensive Guide to Manganese Processing Equipment

2024.3.27 5. Rotary Dryers: Rotary dryers are used to dry manganese ore before further processing, reducing moisture content and improving efficiency. Rotary drum dryers are commonly used in manganese processing operations. 6. Ball Mills: Ball mills are used to grind manganese ore into fine particles, facilitating the extraction of manganese from the ore ...

consulter en ligne

- broyage à boulets mills

- Moulins Miniers Balle De Machines

- aplicaciones molienda planta

- utilisation du charbon comme four de ciment

- quienes inventaron los primeros molinos

- le concassage de pierres servengue portugais

- india piedra planta trituradora

- acmpowder revêtement moulin de meulage

- fonction de disque gris dans le processus de broyeur de pierres à chaux

- shaker écrans Indonésie vendre

- machine pour meules origan

- indonesie machine d extraction de charbon a vendre

- brûleur à charbon pulvérisé pakistan

- Concasseurs mobiles granit Écrans de

- broyeur depuis le fabricant de porcelaine