The six main steps of iron ore processing - Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static

consulter en ligne

Crushing and Screening Handbook - AusIMM

Track-mounted crushing plants – fully mo-bile jaw, cone or impact crushing plants, with or without screens, and equipped with open or closed circuit and discharge conveyors. Easily

consulter en ligne

(PDF) Crushing and Screening Handbook - Academia

This paper assesses a number of factors affecting the performance of the crushing plant by addressing the critical design parameters and consideration of ore characteristics, operability

consulter en ligne

Comminution and classification technologies of iron ore

2022.1.1 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct

consulter en ligne

IRON ORE CAPABILITY

The organisation boasts extensive knowledge in iron ore beneficiation for hematite and magnetite, from simple crushing and screening for direct shipping ore (DSO) to more complex

consulter en ligne

Mobile Crushing and Screening Plant Applications for Small- to

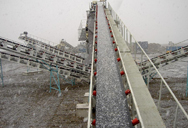

Mobile Crushing and Screening Plant Applications for Small- to Medium-Sized Iron Ore Projects. There is now a new generation of mobile crushing and screening plant systems available

consulter en ligne

Advances in screening technology in the mining sector

Screening is mainly used in the mining sector in primary and secondary crushing systems (Fig. 3), coarse screening (scalping) in the pre-heap leaching process, fine screening and fine-grain

consulter en ligne

Crushing Plant - an overview ScienceDirect Topics

Developments in iron ore comminution and classification technologies. A. Jankovic, in Iron Ore, 2015. 8.2.4 Mobile crushing and screening plant applications for small- to medium-sized iron

consulter en ligne

Ore Beneficiation - an overview ScienceDirect Topics

Screening is an important step for dry beneficiation of iron ore. Crushing and screening is typically the first step of iron ore beneficiation processes. In most ores, including iron ore, valuable

consulter en ligne

Crushing Services and Material Supply – Iron Mine Contracting

Iron Mine Contracting offer a range of crushing, screening and material rehandle options at production rates up to 1500tph. We own and operate a fleet of track mounted plant for rapid mobilisation and production of aggregates, stemming and road base, while our modular electric equipment can produce run rates of up to 1500tph in bulk environments.

consulter en ligne

Ore, Rock Aggregate Screening (Complete Guide)

2016.6.20 A-Z Guide to Screening Ore, Rock Aggregate. A simple definition of a “screen” is a machine with surface(s) used to classify materials by size. Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening surface”.

consulter en ligne

NextGen crushing plant - Mineral Resources

Nextgen crushing plant MinRes is a leading diversified resources company, with extensive operations in lithium, iron ore, energy and mining services across WA. Nextgen crushing plant ... fully modular ‘plug and play’ crushing and screening facility – pin connected, ...

consulter en ligne

Iron Ore Processing: From Extraction to Manufacturing

2024.4.26 Learn about the key stages in iron ore processing, including crushing, screening, and beneficiation techniques for optimal resource utilization. +86 13810565920 xlyin@xinhaimining

consulter en ligne

# 1 Crushing Screening Plant in India Torsa

Iron ore crushing and screening for steel industry; Limestone crushing screening for cement industry; ... Torsa is the biggest crushing screening plants in India who specialize in producing stone crushers, cone crushers and automatic crushing plants. info@torsa Toll Free :

consulter en ligne

Tata Steel commissions iron ore processing plant in Odisha

2021.11.24 The plant design includes three stage crushing and screening. SENSEX 79,486.32 -55.47. NIFTY 24,148.20 -51.15. ... Tata Steel commissions iron ore processing plant in Odisha ...

consulter en ligne

(PDF) ORE SEPARATION BY SCREENING - ResearchGate

2017.3.3 Ore separation by screening methods are highlighted in this report. ... On a crushing and screening plant, punch pla tes or perforated plates are mostly used on scalpe r .

consulter en ligne

Seneca Crushing and Screening Equipment South Africa

Our fleet of mobile crushing and screening units provides you with on-site crushing and screening solutions, bringing the equipment directly to your project location. Additionally, we also offer mobile crushers for hire, allowing you to access our state-of-the-art equipment along with a certified operator.

consulter en ligne

Kleemann Screening Plants: Global Product with Versatile Applications ...

India’s total Iron Ore production for the year CY19 was 231 Million MTs, which enabled 90% (111 million MTs). Main Menu. Home; ... Titan Crushing Screening Plants ranging from 50 to 500 tph and its M-Sand and P-Sand Plants under its Diamond brand name are available in different combinations and capacities for processing various types ...

consulter en ligne

Beneficiation of Iron Ores - IspatGuru

2014.4.3 Fig 3 Types of processing ores. The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore. The wet process consists of multi-stage crushing followed by different stages of washing in the form of scrubbing and / or screening, and classification etc., but the advantage is only partial removal of adhered alumina and free

consulter en ligne

Cost Analysis for Crushing and Screening – Part II

different/multiple crushed products within a designed crushing circuit. 1.3 Purpose and Goals The purpose of this master thesis will be further development of the Cost Analysis for Crushing and Screening Model. The base of this project will be Cost Analysis for

consulter en ligne

Kleemann screening plants for iron ore mining in Odisha

More than 20 excavators having bucket capacity from the range of 2.1 cubic meter (cum) to 4 cum are used for excavation, handling and loading of the ore, followed by approximately 140 mining and dumping trucks having capacity from 19.5 cum to 24 cum to help transport the material from the mines to screening plants to get the output in required sizes.

consulter en ligne

MAX Plant Crushing, screening, conveying mineral processing

MAX Plant produces custom modular, fixed, mobile and portable crushing, screening, conveying and mineral processing equipment in Australia. We work with crushing contractors, site owners and operators to design and manufacture the perfect crushing, screening and mineral processing solutions for your application.

consulter en ligne

Eco-Match Crushing, Screening, Mining, Aggregates, Rock, Plant

Eco-Match processes material predominantly derived from borrow pit, mining, waste rock dump or excavation operations. We currently have the plant and capabilities to produce various grades of aggregate material mostly used in road construction, as well as the capability to process numerous different resource types as per client tonnage requirements.

consulter en ligne

Beneficiation, sintering, and processing of raw materials for the iron ...

for preparing sized ore. For this purpose, ore handling plants employing crushing and dry screening have been set up by the various iron and steel plants. These plants have not been able to give satisfactory performance owing to the extremely sticky nature of iron ores treated, particularly during the rainy season. Not only do the

consulter en ligne

Crushing - Metso

Metso is combining our legacy and expertise to introduce the Mining Crushing Stations. These 2 modular crushing and screening plants are unique, cost-efficient and productive, and designed to provide significant time and resource savings. The Mining Crushing Stations are made up of 2 solutions: FIT™ Stations and Foresight™ Stations.

consulter en ligne

Iron ore crushing and screening process - SBM Ultrafine Powder

2022.8.3 2. Iron ore screening process: Iron ore screening equipment generally uses a circular vibrating screen to screen the materials after the second crushing. Generally, materials with a size of 10mm or less can be screened for dry selection. After screening, materials with a size of 10-40mm enter the fine crusher for fine crushing.

consulter en ligne

The impact of new technologies on the iron ore screening

2024.1.16 1 Metal 7 Inc, 285, des Pionniers, CP 1590, G4R 4X9, Sept-Îles, Québec, Canada 2 WooDEM, Květoslava Mašity 291 CZ-25231 Všenory, Czech * e-mail: agandrade@metal7 Received: 16 January 2024 Accepted: 13 March 2024 Abstract. The iron ore screening process plays a pivotal role in determining the dimensions of pellets that enter

consulter en ligne

Crushing Plant Flowsheet Design-Layout - 911Metallurgist

2016.3.11 In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, ... As a review of the screening phase in a plant, it should be asked if production is being sacrificed for screen surface life.

consulter en ligne

Iron Ore - Geoscience Australia

2023.12.19 Iron ores are rocks from which metallic ... magnetite ores require initial crushing and screening but also undergo a second stage of processing using ... River: The operation at the Savage River mine, located 75 km southwest of Burnie, processes and beneficiates magnetite ore to produce magnetite pellets at its plant at ...

consulter en ligne

>> Next:Concassage De Roche Et De Gravier

- concasseurs de calcaire kingston

- recherche de broyeurs a marteaux

- diagramme de fluide de vidoir

- un croquis simple de la France de l'utilisé de bavures

- problème à haute température sur raymond moulin

- impact de la pollution provient de concasseur de pierre

- achat de carbonate de calcium en azerbaïdjan

- roues basse pression pour sable

- liste des usines pakistan openhand mills association

- c d usines de concassage

- caoutchoucs de concasseur

- piste concasseurs ventes dans uae mod le

- mmd charbon de concasseurs Indonésie mâchoires concasseur mobile

- defauts marteau de concassage

- facteur de finesse en écrasant