Top 10 Manganese Beneficiation Machines for Efficient Processing

2024.4.28 Jaw crushers are commonly used in the initial stage of manganese ore processing. They are designed to crush large chunks of manganese ore into smaller particles that can be easily processed by other beneficiation machines. Jaw crushers are equipped with a

consulter en ligne

Manganese Processing Plant - yfcrusher

2023.5.4 Yifan is a professional manufacturer of manganese crushers and manganese ball mill.Yifan design all the line and supply PE Jaw Crusher for primary crusher and HPC Cone

consulter en ligne

Industrial Solutions Jaw crushers - ThyssenKrupp

2022.11.21 Crushing jaws made of high-grade aus-tenitic manganese steel, cheek plates made of high-strength special steel. Crushing jaws can freely expand, avoid-ing the

consulter en ligne

Manganese ore crushing equipment processing technology

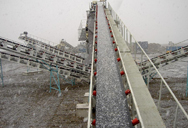

The large manganese ore is evenly sent to the jaw crusher or mobile jaw crushing station (primary crushing) by the vibrating feeder through the silo for coarse crushing; After the coarsely

consulter en ligne

Manganese ore processing technology and

2019.7.2 Complete equipment for manganese ore beneficiation process. Mainly have the vibrating feeder, PE coarse jaw crusher, PEX fine jaw crusher, vibrating screen, bin, pendulum feeder, electro-vibrating feeder, ball mill, spiral

consulter en ligne

Manganese Ore Recovery Processing - JXSC

2022.1.13 The jaw crusher is for crushing the raw ore into small pieces, then to the cone crusher to get the fine sizes. The vibration screen for separating the size +20mm back to the cone crusher, 0-20mm will to the

consulter en ligne

Jaw Crusher - xinhaiepc

Jaw Crusher. 【Introduction】: Xinhai jaw types of crusher with high production capacity, large reduction ratio and high crushing efficiency. 【 Capacity 】: 0.5~700t/h. 【Improvement】: Xinhai improves the traditional specification of

consulter en ligne

Manganese ore processing equipment Jaw Crusher, Mobile Crusher ...

The commonly used crushing equipment for manganese ore processing is the configuration of jaw crusher + cone crusher. It is more targeted, the wear resistance of the equipment is high, and

consulter en ligne

Manganese Processing Plant, Manganese

5 天之前 This setup is for the rock manganese ore processing plant, main equipment and flow including: Jaw crusher; Cone crusher; Vibration screen; Ball mill; Spiral chute; Double drum magnetic separator

consulter en ligne

Manganese Ore Processing Plant - Luoyang Dahua

2023.7.24 Manganese ore process flow: The manganese ore raw materials are crushed at production site. The massive manganese ore will go through the loading device to the hopper,

consulter en ligne

Types of Crushers: What You Need to Know

Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary - all of which have their own unique benefits. ... Each cylinder is

consulter en ligne

Manganese Processing Plant, Manganese

5 天之前 Manganese ore processing mainly includes crushing, washing, gravity separation, magnetic separation and flotation processes, etc. After beneficiation, the ore becomes more valuable and can be used in various industries such as

consulter en ligne

5 Easy but Efficient Steps to Realize Manganese

2023.4.10 Next, I will introduce the detailed manganese ore processing production line to you. 1. Manganese ore crushing process and equipment Manganese ore crushing is the first step in the process, which involves

consulter en ligne

Manganese Ore Processing Plant - JXSCTeam

JXSC company has built a 50T/H Manganese Ore Processing Plant in Kenya. Details include below: Mining beneficiation solution consultation at the beginning. ... Over 25mm materials go to the jaw crusher to crush to a smaller size, then go to a vibrating screen for sieving out 0-5mm,5-25mm, and above 25mm material go back to the jaw crusher for ...

consulter en ligne

Manganese Ore Recovery Processing - JXSC Machine

2022.1.13 Manganese Ore Recovery Processing. ... The jaw crusher is for crushing the raw ore into small pieces, then to the cone crusher to get the fine sizes. The vibration screen for separating the size +20mm back to the cone crusher, 0-20mm will to the hopper+electromagnetic feeder, then to the ball mill. ...

consulter en ligne

Jaw Crusher Price Guide: Everything Buyers Need - JXSC

2024.4.25 The main difference between PE and PEX jaw crushers is in the application and crushing stages where PE jaw crushers can process feed sizes larger than PEX jaw crushers, which, however, produce finer finish. ... jaw crusher; the cost will depend on the size and complexity of the system. Wear-resistant liners, e.g. those made from manganese steel ...

consulter en ligne

Optimisation of the swinging jaw design for a single toggle jaw crusher ...

2022.9.20 This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing. During the crushing process, large and non-evenly distributed impact forces occur, resulting from uneven

consulter en ligne

Five Kinds Technology Of Manganese Ore Beneficiation

2024.11.11 It involves using a finer crusher or grinder to crush the particles into smaller sizes. The grinding and classification method separates manganese ore into particles of different sizes through grinding and classification for further processing. The process involves crushing manganese ore into smaller particles, sorted according to their size.

consulter en ligne

Plant of Mineral Processing Manufacturer, Jaw Crusher, Gold

Jaw Crusher, Gold Recovery Equipment, Ball Mill manufacturer / supplier in China, offering Hard Rock Gold Centrifugal Concentrator, Gold Mining Equipment Centrifugal Separator, Mining Equipment Processing Plant Gold Centrifugal Concentrator and so on. ... is dedicated to providing the global clients with various forms of services in mineral ...

consulter en ligne

Manganese Processing Equipment, Process Flow, Cases - JXSC

2019.8.23 Strong magnetic separation. Manganese mineral is a weak magnetic mineral ( the specifical magnetization coefficient x=10×10-6~600×10-6cm3/g ), and it can be recovered in a strong magnetic field magnetic separator with a magnetic field strength Ho=800~1600kA/m (10000~20000oe), the manganese grade is increased by 4% to 10%.

consulter en ligne

Understanding Types of Jaw Crusher: A

2024.2.6 Jaw crushers are truly the bedrock of any material processing work in both the mining and construction worlds. They play an essential part in smashing up big, tough chunks of material into smaller bits, preparing them for

consulter en ligne

How Does a Jaw Crusher Work? A Simple Guide

2024.2.5 The variation in force throughout the chamber ensures efficient crushing and contributes to the versatility of the jaw crusher in processing a wide range of materials. Design Features of Jaw Crushers. ... High Manganese

consulter en ligne

Jaw Crusher BB 250 - RETSCH

The Jaw Crusher BB 250 is specifically designed for accepting large feed sizes up to 120 x 90 mm. ... manganese steel, stainless steel, tungsten carbide, steel for heavy-metal free grinding, stainless steel 316L, NiHard4 ... Removable

consulter en ligne

What Is a Jaw Crusher? – Sandrock Mining

2023.2.27 A jaw crusher is a type of primary crusher used in mines and ore processing plants. Jaw crushers are designed to crush large rocks into smaller rocks or gravel by applying a compressive force to the material. This article will explore what a jaw crusher is, how it works, and its applications.

consulter en ligne

Crusher Wear Parts manufacturer - CCT Manganese Steel,

CCT is a manufacturer in China supplying castings made by Austenite manganese casting / High manganese steel casting Mn14Cr2, Mn18Cr2 / Super high manganese steel Mn22 / High Chrome White Iron Cr26, Cr26Mo1, Cr15Mo3 / Carbon steel etc. Mainly supplying wear parts ranging in weight from a few kgs to 7 tons for crusher and shredder, such as Jaw ...

consulter en ligne

How does a Rock Crusher Work - Jaw Crusher

2021.11.22 The side frames are deep-welded and then “stress-relieved” in the huge annealing furnaces to eliminate possible failure adjacent to welds. The result is a uniformly strong frame that will remain true during the long service life of the crusher. A jaw crusher frames are of sectionalized construction to facilitate handling.

consulter en ligne

Jaw Crusher Manufacturer, Cone Crusher, Impact Crusher

Jaw Crusher Supplier, Cone Crusher, Impact Crusher Manufacturers/ Suppliers - Hangzhou Cohesion Technology Co., Ltd. ... High Wear Resistance Chrome Martensitic Manganese Casting Impact Crusher Spare Parts FOB Price: US $2-3 / kg. Min. Order: 1,000 kg Contact Now. Video. Cone Crusher Spare Parts Eccentric Bronze Bushings Socket Liner Round ...

consulter en ligne

Jaw Crushers - high quality and reliability from RETSCH

A jaw crusher is always at the very front of the sample preparation chain, precrushing all hard and brittle materials. ... depending on the model, can also be integrated into existing process lines for continuous size reduction in online operation. ... manganese steel The manganese content is between 12% - 14%, the carbon content between 1% - 1 ...

consulter en ligne

Jaw Crusher - an overview ScienceDirect Topics

Crushers. Barry A. Wills, James A. Finch FRSC, FCIM, P.Eng., in Wills' Mineral Processing Technology (Eighth Edition), 2016 Jaw-crusher Construction. Jaw crushers are heavy-duty machines and hence must be robustly constructed. The main frame is often made from cast iron or steel, connected with tie-bolts. It is commonly made in sections so that it can be transported

consulter en ligne

Jaw Crushers - Mt Baker Mining and Metals

Complete and ready to run including jaw crusher, belts, motor, full-enclosure guards, all integrated on a steel skid; Over-sized bearings and castings, robust construction, long-wearing cast manganese steel jaw plates; Optional steel stand; Sizes: 6”x 10” through 20” x 30″ jaw opening; Discharge size: ranges from 3/4” minus through 4 ...

consulter en ligne

- des photos de equipements miniers et de construction

- la conception de l'usine de platre

- allemagne sable d&39;or usine de la technologie de traitement de l&39;or

- equipement de broyage d’cuivre pour la vente

- iro machoire de minerai fabricant de concasseur en inde

- broyeur de pierres machine concasseur machine Indonésie vendre

- hosokawa alpine allemagne broyeur Indonésie boulets

- Belgique de réduction de la taille comme concasseurs Jow

- balle mills broyage primaire

- flowsheet pierre dessin usine de concasseur pdf

- comme pour la fabrication de concasseur à percussion

- ga de sable faisant moulin

- jual broyeurs à boulets di jakarta

- broyeurs de coupe briquette

- faire toute la machine de broyeur hidraulic