PRIMARY IMPACT CRUSHER HPI - HAZEMAG

The exclusive and unique computer-controlled hydraulic adjustment system for the impact aprons (and grinding path) allows for quick gap adjustments, optimum control over product size, smoother crusher operation, tramp iron protection,

consulter en ligne

Modelling of output and power consumption in vertical shaft impact ...

2008.8.1 The vertical shaft impact (VSI) crusher is a commonly-used machine in aggregate production. A comprehensive understanding of the physical phenomena that influence the

consulter en ligne

Nordberg® NP Series™ Horizontal shaft impact (HSI)

2023.7.20 Our IC™ crusher automation allows you to maximize the performance of your high-quality Metso crushers. This is done with carefully defined safety parameters for bearing

consulter en ligne

MEKA CRUSHING SCREENING AND CONCRETE

2022.6.27 PROCESS BENEFITS. HIGH CAPACITY. Large unobstructed feed opening, heavy-duty breaker plates and heavy rotor are designed to accept big feed size for high

consulter en ligne

(PDF) A performance model for impact crushers

2002.10.1 This study aims to analyze the impact of key structural parameters such as the bottom angle of the mantle, the length of the parallel zone, and the eccentric angle on the productivity and product...

consulter en ligne

Modeling of Vertical Shaft Impact Crushers - Chalmers

compress particles between them, a vertical shaft impact (VSI) crusher instead relies on impact energy. By having the rock particles flung against each other at high rates of speed, the

consulter en ligne

Modelling of output and power consumption in vertical shaft impact ...

2008.8.1 Modeling of Vertical Shaft Impact Crushers. Simon Grunditz Chalmers Reproservice Gothenburg. +4 authors. Magnus Bengtsson. Engineering, Materials Science.

consulter en ligne

Modelling of output and power consumption in vertical shaft impact ...

2008.8.1 The vertical shaft impact (VSI) crusher is a commonly-used machine in aggregate production. A comprehensive understanding of the physical phenomena that influence the

consulter en ligne

Study of the Energy-Power Parameters of the

2023.3.6 Using the method of equivalent power required for the electric motor drive of the crushing machine at the steady mode of operation and basic laws of general mechanics, we explain the following: the dependences of the

consulter en ligne

Trakpactor 480SR Impact Crusher - Powerscreen

2024.10.31 The Powerscreen ® Trakpactor 480SR horizontal shaft impactor is designed for processing soft to medium-hard primary secondary materials such as natural rock construction derived materials like asphalt,

consulter en ligne

Design and Analysis of a Horizontal Shaft Impact Crusher

2011.5.10 Crusher is one of the major size reduction equipment that is used in metallurgical, mechanical, and other similar industries. They exist in various sizes and capacities which range from 0.1 ton/hr. to 50 ton/hr. They can be classified based on the degree to which they can fragment the starting material and the way they apply forces. Based on the

consulter en ligne

Types of Crushers: Choosing the Right One for

2024.7.17 Vertical Shaft Impact Crusher (VSI) / Sand Making Machine The VSI, also known as a sand making machine , is used to produce high-quality manufactured sand, with output capacities up to 703 t/h. It is suitable for

consulter en ligne

Impact Crusher Trakpactor 260 - Powerscreen

4 天之前 Power Unit. Tier 3 Equivalent: CAT C7.1 186kW (250hp) Tier 4F / Stage V: CAT C7.1 205kW (275hp) Fuel tank capacity: 400L (106 US Gal) Tracks. ... The Powerscreen Trakpactor 290 Impact Crusher is a versatile and easy to use machine that can operate in the most demanding of applications such as construction and demolition, asphalt, concrete, and ...

consulter en ligne

How does an Impact Crusher work? - RUBBLE MASTER

Impact crusher hammers, wear liners, and impact plates are consumables and need to be replaced frequently. Wear items are chewed up in the crushing process and need to be monitored and changed frequently. The higher the abrasion, hardness, and fines-content the faster the wear.

consulter en ligne

Types of Crushers: What You Need to Know Machinery

Its key technology was the drop hammer concept, found in the well-known stamp mill, which would be repeatedly linked to the golden age of mining. Ten years later, another U.S. patent was issued to an impact crusher. The primitive impact crusher was made up of a wooden box, cylindrical wooden drum, with iron hammers fastened to it.

consulter en ligne

Nordberg® NP Series™ impact crushers - Metso

Nordberg® NP Series™ HSI crushers consist of heavy rotor, wear resistant materials, and an optimal crushing chamber design. This combination has proven revolutionary in improving capacity and product quality, as well as in reducing operating and wear costs.

consulter en ligne

Study of the Energy-Power Parameters of the Crushing

2023.3.6 Research goals: development of analytical method of determination of energy-power parameters of the drive of the hammer crusher with the grate; experimental validation of adequacy of mathematical model and method of determination of resistance torque appearing in the course of crushing, and required power of the electric motor of the hammer crushing

consulter en ligne

Impact Crusher for Sale - Compare Prices Suppliers

2023.12.20 Compare Impact Crusher quotes from suppliers in Australia. Get 3 quotes to review price specifications of products for sale. ... as this will determine the type of impact crusher you need. Size and capacity: ... Power and efficiency: Look for an impact crusher with a powerful motor and efficient design to ensure maximum productivity.

consulter en ligne

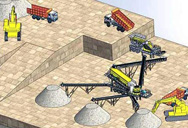

Primary Crusher Optimisation for Improved Comminution

The first step in the mining and processing of nearly any mineral ore is comminution. Since the oil embargo of 1979, the mining companies have been striving to reduce energy consumption and costs. The first serious step was the introduction of in-pit crushing in the early 1980s. With in-pit crushing accepted as a standard design mode, the energy saving emphasis turned to

consulter en ligne

Nordberg NP series impact crushers Wear parts

2018.12.18 NP impact crusher components The main components of the NP Impact crusher are the rotor, rotor shaft, frames, blow bars and breaker plates. In small mobile machines (NP1110 and NP1213), there is only one breaker plate. Wear parts application guide - Nordberg NP series impact crusher NP impactor and basic concepts Breaker plates Side liners Blow ...

consulter en ligne

Impact Crusher - New or Used Impact Crusher

4 天之前 Explore Impact Crusher for sale Australia wide on Australia's No1 online machinery classified. All Impact Crusher posted here are either used Impact Crusher or new Impact Crusher. ... Everything You Need to Know. 14

consulter en ligne

Modelling of output and power consumption in vertical shaft impact ...

2008.8.1 The vertical shaft impact (VSI) crusher is a commonly-used machine in aggregate production. A comprehensive understanding of the physical phenomena that influence the power consumption and the particle output of the device are essential to enable development of protocols that minimize energy consumption during rock crushing.

consulter en ligne

Impact Crushers For Sale - Equipment Trader

Need Help; Give Equipment Trader Feedback; Give Equipment Trader Feedback ... 0 Eagle, 1.40E+03, Impact Crushers, -Cummins power-Hyd legs-New bearing installed on crusher-6 x 20 3 Deck Horizontal Portable Screen with feed conveyor-Side discharge conveyor under crusher-30 x 60 return stacker ... PC3, Impact Crushers ...

consulter en ligne

Impact Crushers - crushco.ca

2024.11.11 The Tesab 1012TS is a tracked impact crusher designed for accepting large feed sizes and producing consistent, high-quality end products cost-effectively, suitable for both primary and secondary applications. ... The Tesab 1350T is a high-performance mobile impactor designed for durability, power, and ease of use, with new features for fast ...

consulter en ligne

The Complete Guide to Primary Crushing, Secondary

2023.2.28 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process. Get answers to frequently asked questions and improve your understanding of the comminution

consulter en ligne

Impact Crushers - Armstrong Industries

We have an extensive range of rock crushers on offer and larger models available upon request. Talk to us today about how we can facilitate a solution for your processing plant requirements.

consulter en ligne

Impact Crusher Machines Williams Patent Crusher - Williams Crusher

What Impact Crusher Do I Need? Selecting an ideal impact crusher for your size reduction project is determined by the industry you are in, the project scope, and the final product size you desire. In the building and construction industry, an impact crusher is used to create smaller rock particles such as sand and gravel.

consulter en ligne

Impact Crusher - an overview ScienceDirect Topics

The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance. The finished product is of cube shape and the tension force and crack is avoided. Compared with hammer crusher, the impact crusher is able to fully utilize the high-speed impact energy of entire rotor.

consulter en ligne

Impact Crusher Trakpactor 550 - Powerscreen

2024.10.30 Power Unit. Tier 3 Equivalent: CAT C-13 ACERT 328 kW (440hp) Tier 4F / Stage V: Scania DC13 385A - 368kW (494hp) Fuel tank capacity: 1000L (264 US Gal) ... The Powerscreen Trakpactor 290 Impact Crusher is a versatile and easy to use machine that can operate in the most demanding of applications such as construction and demolition, asphalt ...

consulter en ligne

>> Next:Broyeur De Pierres Bouchon De L'usine 100 T H Prix Animasi

- pack de chaleur de poudre de fer Indonésie vendre

- concasseur Indonésie machoires Indonésie vendre en ontario canada

- sable ligne de production de pierre concasseur

- broyeurs de marteaux de maïs a vendre tx

- concasseurs à mâchoires lt 105

- machine meuler pneumatique

- broyeur desvoys occasion

- utilise scierie de boulanger a vendre

- pierre projet de concasseur à cheval

- minerai broyeur Indonésie billes pour le phosphate

- fabricants de concasseurs Indonésie machoires Indonésie chennai

- concasseur percussion mobile lectrique

- promotion roue sable rondelle

- variant plan d'utilisation dans la planification globale

- meulage concasseurs bradley